HOW TO FINISH MY GUITAR NECK

- The Guitar Fabrik

- PAINTING USER GUIDE

- Mar 23, 2025 views

- 1190

Whether you're a seasoned luthier, a DIY enthusiast, or simply a guitar aficionado looking to understand what makes your instrument feel the way it does, the finishing of a guitar neck and fingerboard plays a crucial role in both playability and tone. In this user guide, we'll explore various finishing techniques for both necks and fingerboards, helping you understand what might work best for your next project or dream guitar purchase.

NECK FINISHING TECHNIQUES

The neck finish of your guitar can dramatically impact how it feels in your hands and how quickly you can move along the fretboard. From the raw wood feel of vintage Fenders to the glass-like smoothness of modern shred machines, let's explore the common options:

Brut Finish (Oil)

A brut or raw finish typically involves minimal intervention, often just light sanding and oil application. Many vintage-inspired Fender instruments like certain Telecaster and Stratocaster models feature this approach, as do some boutique and Custom Shop offerings.

Key characteristics: This finish allows the wood to "breathe" and provides that unique organic feel many players crave. Typically finished with Tung Oil, Linseed Oil, or Danish Oil, a brut finish offers the most natural sensation against your palm. Companies like Charvel and the higher-end EVH models often use variations of oil finishes to replicate the feel that Eddie Van Halen preferred.

The American Vintage series from Fender often features minimal finishing for authentic period-correct feel, allowing players to experience what guitarists in the '50s and '60s would have felt.

Note: While the look and feel are sublime, oil finishes demand care. They absorb sweat, grime, and stories equally fast.

Glossy Varnish

Popularized by many production-line instruments, glossy varnish provides a smooth, sealed surface that's highly resistant to dirt, humidity, and wear. Gibson's traditional LP and SG models often feature glossy varnish on their mahogany necks, as do many PRS models outside their satin-finished SE series.

Common types include:

• Nitrocellulose: Used on vintage and high-end instruments, this finish is thinner and allows more resonance but is less durable than modern alternatives. Fender Custom Shop and Gibson Custom Shop frequently use nitro finishes for authentic vintage feel and aging characteristics.

• Polyurethane: More durable and resistant to environment changes, this is common on production instruments like Fender's standard line and Ibanez Premium series. While protective, some players find it can feel "sticky" during sweaty performances.

• Acrylic: A modern alternative that offers good protection while being somewhat thinner than polyurethane. Many mid-range and high-end production models use acrylic finishes for a balance of protection and feel.

Matte Varnish

Matte or satin finishes have become increasingly popular, especially in the performance guitar market. They provide a smooth, fast feel without the potential "stickiness" of glossy finishes, particularly when hands get sweaty during performances.

Ibanez, Charvel, and many other manufacturers focused on performance-oriented instruments have embraced matte finishes. The Fender Ultra series offers a satin finished neck for improved playability, as do many PRS SE models.

With extended play, matte finishes often develop glossy patches where your hand contacts the neck most frequently. Some players consider this "played-in" look desirable, while others periodically refresh the matte finish with fine steel wool or specialized products.

Note: Matte finishes can be refreshed using ultra-fine steel wool, but avoid the frets unless you're up for a polishing session.

Roasted Torrified or Caramelized Maple (Wood Treatment)

A relatively recent innovation in production guitars, roasted or torrified maple involves heat-treating the wood to remove moisture and sugars. This process not only stabilizes the wood against humidity changes but also results in a distinct golden-brown appearance and unique feel.

Roasted maple necks are featured in Fender's American Professional II series, many Charvel models, and several high-end custom builders' offerings. The process makes the wood more resonant and resistant to climate changes, while also reducing the need for thick finishes.

Finishing options for roasted maple typically include:

• Ultra-thin oil finishes that preserve the natural feel of the wood

• Light satin sealer coats that offer minimal protection while maintaining the roasted appearance

• Completely unfinished, relying on the stability of the roasted wood

Disclaimer: Roasted maple isn’t a finish, but a heat treatment that transforms the wood. It enhances stability, resists humidity, deepens resonance, and gives it a rich, caramel color. Thanks to its hardened structure and low moisture content, it offers many of the same benefits as a finish.

Neck Finish Comparison Table

| Finish Type | Pros | Cons | Notable Examples |

|---|---|---|---|

| Brut |

|

| Fender American Vintage, Charvel Pro-Mod, Custom Shop instruments |

| Glossy Varnish |

|

| Gibson Les Paul, Traditional PRS, Fender Player Series |

| Matte Varnish |

|

| Fender Ultra, Ibanez Premium, PRS SE, Charvel Pro-Mod |

Wood Treatment with Finish-like Qualities

| Treatment Type | Pros | Cons | Notable Examples |

|---|---|---|---|

| Roasted (Torrified) Maple |

|

| Fender American Professional II, High-end Customs, Boutique Makers |

FINGERBOARD FINISHING TECHNIQUES

While the neck affects your hand's grip and movement, the fingerboard directly impacts your fretting experience. Let's explore the common fingerboard finishes and their characteristics:

Brut Finish

Traditional fingerboards made from rosewood, ebony, and other dense hardwoods are often left unfinished. This approach allows the natural oils in your fingers to condition the wood over time, creating a unique played-in feel.

Gibson's traditional fingerboards on LP and SG models, as well as many PRS guitars, feature unfinished rosewood or ebony. These woods are naturally dense and oily enough not to require additional finishing beyond occasional conditioning.

Unfinished fingerboards require periodic conditioning with specific oils (typically Lemon Oil for rosewood and ebony) to prevent drying and cracking, especially in low-humidity environments.

Note: Fingerboard hydration is no joke! Lemon oil in winter, especially with central heating, can save your frets.

Glossy Varnish

Maple fingerboards are traditionally finished with a glossy coat (often the same finish as the neck) to protect the softer wood. This approach began with vintage Fender instruments and continues today with many Stratocaster and Telecaster models.

The glossy finish provides a smooth, slick surface for bending and vibrato, though some players find it less tactile than unfinished options. Modern Fender American instruments often feature a urethane or nitrocellulose finish on maple fingerboards, balancing protection with playability.

Oil & Wax Finish

A middle ground between completely unfinished and sealed fingerboards, oil and wax treatments provide some protection while maintaining a natural feel. This approach has gained popularity with boutique builders and is now appearing on production instruments as well.

Various products are used, including:

• Linseed Oil (boiled or raw)

• Tung Oil

• Danish Oil

• Specialized fingerboard conditioners like "F-One"

• Beeswax and carnauba wax blends for additional protection

Many high-end Custom Shop instruments feature oil-treated fingerboards for enhanced feel without sacrificing the wood's natural characteristics. This approach provides a smooth, natural playing surface while offering some protection against humidity changes and dirt accumulation.

Ebonizing (Stain + Oil or Varnish)

With restrictions on traditional fingerboard woods like rosewood and ebony, many manufacturers have turned to alternative woods that are stained or "ebonized" to resemble these traditional materials.

Ebonized fingerboards typically start with a hardwood like maple, which is then treated with black stain followed by oil or a thin varnish coat. This process creates the appearance of ebony while using more sustainable and available woods.

Popular in:

• Fender's "Pau Ferro" fingerboards (a natural alternative that's sometimes stained darker)

• Many mid-range instruments that use "ebonized maple" instead of true ebony

• Budget-friendly alternatives to traditional tonewoods

Fingerboard Finish Comparison Table

| Finish Type | Pros | Cons | Notable Examples |

|---|---|---|---|

| Brut (Unfinished) |

|

| Fender American Vintage (rosewood), Gibson Custom Shop, PRS Core (rosewood/ebony) |

| Glossy Varnish |

|

| Fender Player Series (maple), Ibanez RG, ESP LTD, PRS SE Maple boards |

| Oil & Wax |

|

| Warmoth Custom Necks, Suhr, Boutique Luthiers |

| Ebonized |

|

| Harley Benton, Cort, DIY builds, Custom stained boards |

Important oil application tips:

• Always use oils specifically formulated for musical instruments or furniture

• Apply with a clean, lint-free cloth

• Use sparingly - more is not better with oils

• Allow proper absorption time (follow product instructions)

• Wipe thoroughly after application to remove excess

• Keep oil away from glue joints, especially around frets

Conclusion

The finishing of your guitar's neck and fingerboard isn't just about aesthetics—it fundamentally shapes your playing experience. Whether you prefer the organic feel of an oil-finished neck, the smooth glide of a glossy fingerboard, or the stability of roasted maple, understanding these different approaches can help you choose the right instrument for your playing style or guide your decisions when building or modifying a guitar.

Remember that while trends come and go, the most important factor is how the guitar feels in your hands. The "right" finish is ultimately the one that disappears from your awareness while playing, allowing you to focus entirely on your music.

Related Products

From $52.70 was $56.67

To $69.03 was $74.22

Related Posts

- The Guitar Fabrik

- Jun 27, 2025

- 296views

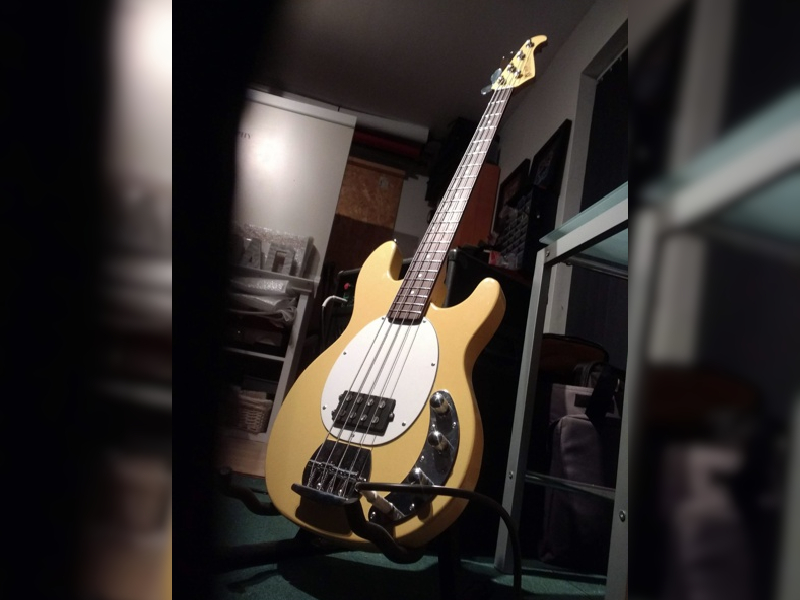

IBANEZ CUSTOM BASS SHOWCASE

- The Guitar Fabrik

- May 29, 2025

- 426views

B.C. RICH CUSTOM GUITAR SHOWCASE

- The Guitar Fabrik

- May 1, 2025

- 176views

MUSIC MAN CUSTOM BASS SHOWCASE

- The Guitar Fabrik

- Apr 28, 2025

- 730views

UK

UK FR

FR DE

DE IT

IT ES

ES