Which Painting for my DIY Guitar Kit

- The Guitar Fabrik

- PAINTING USER GUIDE

- Aug 4, 2025 views

- 549

Which Painting for my DIY Guitar Kit

Introduction

Choosing the right finish for your electric guitar kit is a personal decisions that will affect your instrument’s aesthetic and its tone. The finish you select not only protects the wood from moisture and wear but also influences how the guitar resonates and ages over time. With options ranging from traditional stains to modern polyurethane passing by natural tru-oil, nitrocellulose sprays and eco-friendly water-based finishes, each type brings its own advantages and drawbacks. Understanding their characteristics help you to choose the one that fits your personal taste, playing style, maintenance preferences, and tonal spectrum.

Overview of Guitar Finishing

The finish you choose for your electric guitar kit will significantly impact not only the instrument's appearance but also its sound.

The Importance of Finish in Lutherie:

The finish on an electric guitar serves multiple critical functions that extend far beyond mere aesthetics. While a beautiful finish certainly enhances the visual appeal of your instrument, it plays a fundamental role in protecting the wood from moisture, temperature fluctuations, and physical damage that can occur during regular use.

From a tonal perspective, the finish type and thickness directly influence your guitar's sound characteristics. Different finishes allow varying degrees of wood resonance, affecting sustain, brightness, and overall tonal complexity. A thin finish typically permits more natural wood vibration, while thicker finishes may dampen resonance but provide superior protection.

The finish also significantly impacts the instrument's durability and longevity. A well-applied finish creates a barrier against sweat, oils from your hands, and environmental factors that could otherwise cause wood deterioration or discoloration over time. Additionally, the finish affects the guitar's playability through its interaction with your hands and playing style. Some finishes develop a smooth, worn feel that many players prefer, while others maintain their original texture indefinitely.

Finally, the choice of finish influences the instrument's value retention and aging characteristics. Some finishes develop desirable patina and wear patterns that can enhance both the guitar's character and market value, making your finish selection a crucial long-term investment consideration.

Factors to Consider When Choosing a Finish:

When selecting the ideal finish for your electric guitar kit, several crucial factors will influence your decision and ultimately impact both the instrument's performance and your satisfaction with the final result.

- Skill Level and Experience: is perhaps the most important consideration. Some finishes require specialized equipment, controlled environments, and advanced techniques, while others are more forgiving for beginners. Assess your comfort level with spray guns, buffing compounds, and multi-step processes before committing to a particular finish type.

- Available Time and Workspace: significantly affect your options. Certain finishes demand multiple coats with extended drying times between applications, while others can be completed in a weekend. Consider whether you have access to a dust-free environment, proper ventilation, and temperature control.

- Desired Aesthetic and Style: should align with your guitar's intended look. Vintage-style instruments often benefit from finishes that age gracefully and develop character over time, while modern guitars might call for durable, high-gloss finishes that maintain their appearance.

- Budget Constraints: play a vital role, as finish costs vary dramatically. Factor in not just the finish itself, but also required tools, safety equipment, and potential do-over costs if mistakes occur.

- Durability Requirements: depend on how you'll use the instrument. A guitar destined for heavy touring needs different protection than a studio instrument or display piece.

Finally, consider the wood type and grain of your guitar kit, as some finishes enhance natural wood beauty while others provide opaque coverage for less attractive wood or repairs.

Summary Table of the Benefits of Each Solutions:

| Property | Nitrocellulose | Polyurethane | Tru-Oil | Water-Based |

|---|---|---|---|---|

| Effect on Sound | Natural, slightly bright | Slightly dampened | Natural, enhances resonance | Neutral to slightly dampened |

| Application Process | Easy spray, fast drying | Intermediate, requires careful application | Easy, wipe-on with multiple coats | Easy, brush/spray with fast drying |

| Curing Time | Touch-dry in 1 hour; full cure in a week | 24–72 hours depending on type | 12–24 hours per coat, full build in days | 4 hours drying, full cure in 5–7 days |

| Number of Layers | 2–3 coats | 3–5 coats | 6–12 very thin coats | 2–3 coats |

| Versatility (Colors Possible) | Limited (clear/amber, tints possible) | Wide range of colors and finishes | Limited (clear/amber) | Wide range of colors, can be tinted |

| Resistance / Durability | Moderate, prone to wear and fading | High, very durable and scratch-resistant | Moderate, not as tough as poly | Moderate, good for light use |

| Maintenance | High, frequent re-coating needed | Low, long-lasting with minimal upkeep | Moderate, easy touch-ups | Moderate, occasional touch-ups needed |

| Repairability | Easy, new coats blend well | Difficult, requires sanding and skill | Easy, blendable with new coats | Easy, touch-up friendly |

| Cost | Low | Moderate | Moderate | Low to Moderate |

| Difficulty | Easy | Intermediate | Easy | Easy |

Nitrocellulose Finish

Nitrocellulose lacquer has been the gold standard for guitar finishes since the 1950s, prized by vintage guitar enthusiasts and professional luthiers alike. This classic finish is renowned for its ability to enhance tonal resonance while developing a beautiful patina over time. Despite requiring more skill and patience to apply, nitrocellulose remains the preferred choice for those seeking authentic vintage aesthetics and superior sound quality.

Characteristics of Nitrocellulose:

Nitrocellulose lacquer, often referred to as "nitro," is a traditional finish that has been used on guitars since the 1950s and remains the gold standard for many vintage and high-end instruments. This finish is composed of nitrocellulose dissolved in a solvent, creating a thin, flexible coating that bonds well with wood.

One of the most distinctive characteristics of nitrocellulose is its ability to "breathe" with the wood, allowing the instrument's natural resonance to shine through with minimal dampening effect. The finish cures through solvent evaporation rather than chemical cross-linking, resulting in a relatively thin application that typically measures between 3-5 mils thick.

Nitrocellulose has a particular aging property that many guitar enthusiasts prize. It gradually becomes more porous and brittle over time, developing hairline cracks called "checking" that create the coveted vintage appearance. The finish is also photosensitive, meaning it will yellow and change color when exposed to UV light, contributing to that authentic aged look.

Application-wise, nitrocellulose requires multiple thin coats with adequate drying time between each layer. It's available in both spray and brush-on formulations, though spraying typically yields the best results due to thinner coat and homogeneous application. The finish has a relatively fast track-free time but requires several weeks to fully cure and harden completely. Nitrocellulose can be use to get a vintage, relic finishing.

Pros of Nitrocellulose Finish:

- More Organic Tone: Nitrocellulose allows the wood to breathe and resonate more freely, resulting in enhanced sustain and a warmer tone that many guitarists prefer. In particular, nitrocellulose finish allows thinner application and therefore a lighter finish that doesn't dampen the wood's natural vibrations.

- Vintage Authenticity: Provides the classic look and feel of vintage guitars from the 1950s and 1960s, complete with natural aging characteristics that develop beautiful patina over time.

- Easy Repair and Touch-ups: Damaged areas can be easily sanded and resprayed, blending seamlessly with the existing finish without requiring complete refinishing.

Cons of Nitrocellulose Finish:

- High Maintenance Requirements: Requires careful handling and regular maintenance due to its sensitivity to temperature, humidity, and chemicals.

- Longer Curing Time: Takes significantly longer to fully cure compared to modern finishes, often requiring weeks or months to reach maximum hardness.

- Fragility: More susceptible to scratches, dents, and damage from everyday use, making it less suitable for heavy touring or aggressive playing styles.

- Application Complexity: Requires skilled technique and proper spray equipment, making it challenging for beginners to achieve professional results.

- Environmental Sensitivity: Can react poorly to cleaning products, alcohol, and even perspiration, potentially causing finish damage or discoloration.

- Cost Factor: Generally more expensive than alternative finishes due to material costs and the time-intensive application process.

Polyurethane Finish

Polyurethane has become the industry standard for modern electric guitar finishes, offering exceptional durability and protection for your instrument. This synthetic coating provides a hard, glossy surface that can withstand the rigors of regular playing and transportation better than most other finish options.

Characteristics of Polyurethane:

Polyurethane is a synthetic polymer finish that has become increasingly popular in guitar manufacturing since the 1970s. This finish is created through a chemical reaction between polyols and isocyanates, resulting in a highly durable and protective coating. Polyurethane finishes are available in both oil-based and water-based formulations, with oil-based versions being more commonly used for guitar applications.

The finish creates a thick, hard protective layer that typically ranges from 5-8 mils in thickness, significantly thicker than traditional nitrocellulose finishes. Polyurethane cures through oxidation and polymerization, forming cross-linked molecular chains that create an exceptionally strong and resilient surface. This chemical composition makes it highly resistant to moisture, chemicals, temperature changes, and physical damage.

Polyurethane finishes are known for their excellent clarity and ability to enhance wood grain visibility while providing consistent color retention over time. The finish can be applied in various sheens, from high-gloss to satin, and maintains its appearance with minimal maintenance. Unlike some traditional finishes, polyurethane does not yellow significantly with age and provides superior protection against environmental factors such as humidity fluctuations and UV exposure.

The application process typically involves multiple thin coats with sanding between applications, and the finish generally requires 24-48 hours between coats for proper curing. Once fully cured, polyurethane creates a stable, non-porous surface that effectively seals the wood underneath. PU are generally used to get opaque finishing like standard finishing we found in commerce.

Pros of Polyurethane Finish:

- Exceptional Durability: Polyurethane creates an extremely hard, scratch-resistant surface that can withstand heavy playing and transportation without showing wear

- Moisture Protection: Provides superior resistance to humidity changes, making it ideal for guitars in varying climates

- Low Maintenance: Requires minimal upkeep once applied and cured properly

- Consistent Appearance: Maintains its glossy finish for years without yellowing or significant deterioration

Cons of Polyurethane Finish:

- Effect on Tonality: The thick, hard coating may dampen wood resonance and reduce sustain compared to thinner finishes

- Difficult Repairs: Chips and scratches are harder to touch up seamlessly, often requiring professional refinishing

- Removal Challenges: Extremely difficult to strip if refinishing is desired later, often requiring aggressive sanding methods

- Costly: Although it is used for commerce and production because it is cheaper, if you don’t have a paint gun and don’t do many guitars it will be more expensive than other solutions.

- Difficulty of Application: If you don’t have the correct material it is more complicated to apply as it needs to mix with a hardener.

Tru Oil Finish

Tru Oil represents a unique approach to guitar finishing that bridges the gap between traditional oil finishes and modern protective coatings. This gunstock oil finish has gained popularity among guitar builders for its ability to enhance wood grain while providing moderate protection. Unlike spray-on finishes, Tru Oil is hand-applied and builds up gradually through multiple thin coats, creating a distinctive satin appearance.

Characteristics of Tru Oil:

Tru Oil is a finishing product that sits between traditional oil finishes and modern synthetic coatings. Originally developed by Birchwood Casey for gunstock finishing, Tru Oil has gained popularity among guitar builders for its distinctive properties and ease of application.

Unlike pure oil finishes, Tru Oil contains polymerized linseed oil combined with other resins, creating a finish that penetrates the wood while also building up surface layers. This hybrid nature allows it to enhance the wood's natural grain and figure while providing more protection than a simple oil finish.

The consistency of Tru Oil is relatively thin compared to lacquers or polyurethanes, making it easy to apply with a cloth, brush, or even by hand. It dries to a satin finish naturally but can be polished to achieve varying levels of gloss. The finish builds slowly with each coat, typically requiring 4 to 12 depending on the finishing and proection oyu are looking for (typically needs less coats for a neck)thin applications to achieve full coverage and protection. The number of layers will depend of the final look you’re aiming (the more layers you apply, the glosser the look)

One of Tru Oil's most distinctive characteristics is its ability to create a tactile, organic feel that many players prefer over harder finishes. The cured finish maintains some flexibility and warmth to the touch, while still providing adequate protection against moisture and minor scratches. It also has excellent adhesion properties and rarely requires sanding between coats when applied properly.

Tru-Oil is mostly used to achieve a natural finish that leaves the wood grain visible.

Pros of Tru Oil Finish:

- Easy application: Tru Oil is beginner-friendly and can be applied with a cloth or fingers, making it ideal for first-time guitar builders

- Natural wood enhancement: Brings out the natural grain and beauty of the wood while maintaining a warm, organic appearance

- Quick drying: Each coat dries relatively fast, allowing for multiple applications in a single session

- Repairable: Easy to touch up or reapply if damaged, without needing to strip the entire finish

- Flexible finish: Won't crack easily with wood movement and temperature changes

- Cost-effective: Relatively inexpensive compared to other professional finishing options

- Low odor: Produces minimal fumes during application, making it suitable for home workshops

Cons of Tru Oil Finish:

- Limited durability: Not as resistant to scratches, dents, and wear as polyurethane or nitrocellulose finishes

- Requires multiple coats: Needs several thin applications to achieve desired depth and protection

- Susceptible to water damage: Can show water spots and rings more easily than synthetic finishes

- Regular maintenance: Requires periodic reapplication to maintain protection and appearance

- Heat sensitivity: Can soften or mark when exposed to high temperatures

- Cautious with Coloration: Primarily enhances natural wood tones rather than providing vibrant colors. It can be use along with dye but remember that tru oil itself will slightly darken the wood the more you applied coats and create a slightly amber tint.

Water-Based Finishes

Water-based finishes represent the newest category of guitar finishes, developed as an environmentally friendly alternative to traditional solvent-based options. These finishes have gained popularity among guitar builders for their low toxicity, reduced environmental impact, and ease of application. While relatively new to the guitar finishing world, water-based products offer advantages that make them worth considering for your guitar kit project.

Characteristics of Water-Based Finishes:

Water-based finishes represent a modern, environmentally conscious approach to guitar finishing that has gained popularity among both amateur and professional builders. These finishes use water as the primary carrier instead of traditional organic solvents, making them significantly more eco-friendly and safer to work with in home workshop environments.

The composition of water-based finishes typically includes acrylic or polyurethane resins suspended in water, along with various additives that enhance flow, leveling, and durability. This formulation creates a finish that dries through water evaporation rather than chemical curing, resulting in faster application times and reduced odor compared to solvent-based alternatives.

One of the most notable characteristics of water-based finishes is their crystal-clear transparency, which allows the natural wood grain and color to show through without the amber tinting often associated with other finish types. This makes them particularly suitable for guitars featuring light-colored or exotic woods where maintaining the wood's natural appearance is paramount.

Water-based finishes also exhibit excellent UV resistance, helping to prevent the yellowing and degradation that can occur with prolonged exposure to sunlight. They typically have a medium to high gloss level when properly applied and can be easily adjusted with appropriate additives or topcoats to achieve the desired sheen level.

From an application standpoint, these finishes are generally thinner in consistency than traditional lacquers, requiring multiple thin coats to build up the desired thickness and protection level. They dry relatively quickly, usually within 2-4 hours between coats, making them ideal for builders who want to complete their projects efficiently. Water-Based allows a very wide-range of finishing effects including translucent, opaque, matt, gloss or natural.

Pros of Water-Based Finishes:

- Eco-Friendly: Low VOC content makes water-based finishes safer for indoor use and better for the environment

- Quick drying: Faster curing compared to oil-based finishes, allowing for more efficient application

- Easy cleanup: Tools and brushes can be cleaned with soap and water instead of harsh solvents

- Excellent clarity: Provides crystal-clear protection that won't yellow over time, maintaining the wood's natural appearance.

- Odor-free application: Minimal smell during application and curing process

- Good durability: Modern formulations offer decent protection against scratches and wear

Cons of Water-Based Finishes:

- Potential for grain raising: Water content can cause wood fibers to swell, requiring additional sanding between coats

- Less forgiving application: Requires more careful technique to avoid brush marks and lap marks

- Temperature sensitivity: Performance can be affected by humidity and temperature during application

Recommendations for Different Types of Guitar Kits

With a clear understanding of each finish type's characteristics and trade-offs, selecting the right finish for your guitar kit becomes a matter of matching the finish properties to your specific guitar style and intended use. The choice between vintage authenticity and modern durability will largely determine which finish best serves your project goals.

Summary table for different Finshing style:

| Finish Type | Tru-Oil | Nitrocellulose | Polyurethane | Water-Based |

|---|---|---|---|---|

| Ceruse | Impossible | Not adapted | Optimal | Optimal |

| Translucent | Optimal | Optimal | Not adapted | Optimal |

| Natural | Optimal | Optimal | Not adapted | Optimal |

| Opaque | Impossible | Optimal | Optimal | Optimal |

| Sunburst | Impossible | Optimal | Not adapted | Not adapted |

| Metallic | Impossible | Optimal | Optimal | Optimal |

When choosing the best guitar finish, different products perform better depending on the style you want. Tru-Oil works beautifully for natural and translucent finishes but is impossible to use for ceruse, opaque, sunburst, or metallic styles. Nitrocellulose is very versatile, making it optimal for translucent, natural, opaque, sunburst, and metallic finishes, although it is not suited for ceruse. Polyurethane is ideal for ceruse, opaque, and metallic finishes, but less adapted for translucent, natural, and sunburst looks. Water-based finishes are highly flexible, providing optimal results for ceruse, translucent, natural, opaque, and metallic styles, though they are not the best choice for sunburst.

Recommended Finishes for Vintage Style Guitars:

For vintage-style electric guitars, authenticity is paramount, making nitrocellulose lacquer the top choice for purists seeking that classic look, feel, and tone. This finish perfectly captures the aesthetic of golden-era instruments from the 1950s and 1960s, developing the characteristic aging patina and subtle checking that vintage enthusiasts prize.

Tru Oil serves as an excellent alternative for vintage-style guitars, particularly those with natural wood finishes or sunburst patterns. This oil-based finish enhances the wood's natural grain beautifully while providing that thin, breathable coating that allows the wood to resonate freely – a hallmark of vintage instruments.

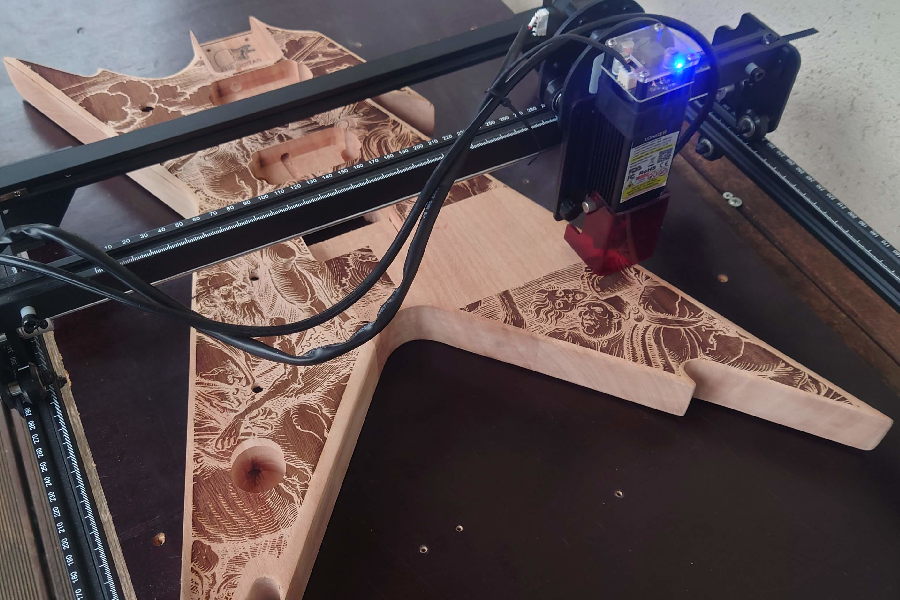

Building on this vintage aesthetic, relicing (or relicage) has become a popular technique to give guitars an authentically aged look. It involves selectively wearing down the finish to simulate decades of use, then optionally sealing it again. While it's most effective, and historically accurate, when used with nitrocellulose, the same idea can be applied to Tru Oil and even water-based finishes, though the results tend to be more subtle. Polyurethane, due to its hardness, is much less forgiving and rarely used for this purpose. Still, with the right approach, relicing can be adapted to nearly any finish to capture that vintage feel.

Key recommendations for vintage builds:

- Fender instruments (Stratocaster, Telecaster, Offsets, Jazz Bass, ...): Nitrocellulose lacquer in classic colors like sunburst, Olympic white, or vintage blonde

- Gibson style guitars (Les Paul, SG, Firebird, ...): Nitrocellulose for that authentic Gibson feel, especially in heritage cherry sunburst or goldtop finishes

- Natural wood showcases: Tru Oil to highlight flame maple tops or beautiful mahogany grain patterns

Avoid polyurethane and water-based finishes for vintage builds, as their modern plastic-like appearance and thick coating can detract from the authentic vintage aesthetic and potentially dampen the wood's natural resonance that vintage guitars are known for.

Recommended Finishes for Modern Style Guitars:

Modern electric guitars typically prioritize durability, consistency, and ease of maintenance over vintage authenticity. For contemporary guitar builds, Nitrocellulose Sprays are one of the top recommendation due to their exceptional durability and resistance to wear, making them ideal for gigging musicians and heavy players who need a finish that can withstand regular use without showing significant wear.

Water-based finishes are an excellent secondary choice for modern guitars, particularly for builders who prioritize environmental consciousness and quick turnaround times. These finishes offer good durability while maintaining clarity and are perfect for guitars with bold, contemporary color schemes or natural wood displays that require UV protection.

For modern guitars with specific wood grain patterns or exotic tonewood tops, water-based finishes excel at preserving the natural beauty while providing adequate protection. They're also ideal for builders working in home workshops due to their low odor and easy cleanup.

Polyurethane remains the gold standard for modern production-style guitars, offering the best balance of protection, longevity, and professional appearance. It's particularly recommended for:

- Guitars intended for frequent live performance

- Instruments with solid colors or metallic finishes

- Players who prefer low-maintenance instruments

- Guitars that will experience temperature and humidity variations

Modern guitar builders should generally avoid nitrocellulose unless specifically pursuing a vintage aesthetic, as it doesn't align with contemporary performance and durability expectations.

Conclusion

Choosing the right finish for your electric guitar kit depends on your priorities, skill level, and desired aesthetic outcome. Nitrocellulose offers vintage authenticity and tonal benefits but requires more expertise, while polyurethane provides maximum durability with easier application for beginners. Tru Oil delivers a natural feel perfect for players who prefer minimal finish thickness, and water-based options offer the best balance of safety and environmental responsibility. Consider your playing style, maintenance preferences, and the guitar's intended use to make the best choice for your specific project.

Related Products

From $20.78 was $39.27

To $182.91 was $215.68

From $27.32 was $37.10

To $174.44 was $217.03

From $30.35 was $37.10

To $193.83 was $217.03

Related Posts

- The Guitar Fabrik

- Jun 27, 2025

- 294views

IBANEZ CUSTOM BASS SHOWCASE

- The Guitar Fabrik

- May 29, 2025

- 423views

B.C. RICH CUSTOM GUITAR SHOWCASE

- The Guitar Fabrik

- May 1, 2025

- 176views

MUSIC MAN CUSTOM BASS SHOWCASE

- The Guitar Fabrik

- Apr 28, 2025

- 725views

UK

UK FR

FR DE

DE IT

IT ES

ES