GUITAR SANDING - DRY VS. WET

- The Guitar Fabrik

- GUÍA: PINTURA GUITARRA

- 19 jun 2025 views

- 213

GUITAR SANDING: DRY VS. WET

Sanding is a key part of the guitar finishing process, used at different stages to smooth surfaces and correct imperfections. This guide explains the difference between wet sanding and dry sanding, when to use each method, and how to perform them properly for optimal results.

What Is Wet Sanding / Dry Sanding?

Wet Sanding uses waterproof sandpaper (usually black), lubricated with water and a drop of neutral soap. It's ideal for achieving ultra-smooth finishes, especially on cured varnish before polishing.

Advantages:

- Removes micro scratches and surface unevenness

- Minimizes dust

- Reduces the risk of deep scratching

- Allows fine control over final finish

Ideal conditions: Clean environment, temperature above 15°C (59°F), and fully cured surface.

Dry Sanding is quicker and more abrasive. It's preferred for leveling between coats, correcting drips, or prepping surfaces before applying more varnish.

Recommended use:

- After first or second coat: spot sanding with P400

- Between base coats: P800 to P1000

- To fix rough or uneven surfaces

To avoid:

- Final coats or high-gloss finishes

- Dusty environments

How to Choose: Wet Sanding vs. Dry Sanding

Use this comparison table to choose the best method depending on your situation. "Handy" refers to being convenient and effective with minimal effort; "Messy" implies more cleanup, water use, and risk of lifting poorly cured finishes.

| Use Case | Dry Sanding | Wet Sanding |

|---|---|---|

| Early coats, spot sanding | OK | Not OK |

| Nitrocellulose lacquer | OK (P400–P1000) | OK (P1000+) |

| Water-based finishes | OK (P400–P800) | OK (P1000+) |

| Oil-based finishes (Tru-Oil) | OK | Not OK |

| Between coats | Convenient | Requires cleanup |

| Final leveling before polish | OK | Best |

| Flatting imperfections | Best | OK |

| Working outdoors or in dust | OK | Best |

| Raw wood / staining prep | OK | Not OK |

| Very fine grit finishing (P1500+) | OK | Best |

| Speed / turnaround | Faster | Slower |

How to Perform Wet Sanding / Dry Sanding

- For Wet Sanding:

- Use waterproof sandpaper (P800 to P2500)

- Add a few drops of neutral soap to the water for better glide and less clogging

- Use light circular or straight motions with minimal pressure

- Check frequently for surface smoothness and stop before going through finish

- Dry the surface thoroughly and inspect under angled light

Caution: Do not wet sand uncured finishes, bare wood, or stained surfaces without a topcoat. Always test first.

- For Dry Sanding:

- Choose appropriate grit (P400–P1000) depending on stage

- Use a sanding block for flat areas and fingers for curves

- Remove dust with a tack cloth or vacuum between passes

- Keep movements even and gentle to avoid uneven patches

Tip: Wear a mask and work in a ventilated area to avoid breathing in dust.

Varnish Compatibility

All our finishes are tested for both methods, but results vary:

- Glossy Varnish: Excellent for wet sanding and polishing

- Matt Varnish: Prefer dry sanding to preserve non-reflective finish

- Satin Varnish: Dry sanding recommended; wet sanding may increase glossiness

- Tru-Oil: Use only dry sanding (wet sanding may affect the oil curing process)

- Nitrocellulose lacquer: Compatible with both methods; wet sanding ideal for polishing stages

- Water-based varnish: Works with both methods once fully cured; avoid wet sanding too early

- Polyurethane varnish: Compatible with dry and wet sanding, but allow full cure before wet sanding

Conclusion

Dry sanding is ideal for fast corrections and surface prep, especially in dusty environments or during early stages. Wet sanding delivers smoother finishes and is best for polishing or refining final coats. By understanding both methods and when to apply them, you'll gain better control over your finish quality.

Related Posts

- The Guitar Fabrik

- 27 jun 2025

- 291views

IBANEZ CUSTOM BASS SHOWCASE

- The Guitar Fabrik

- 29 may 2025

- 421views

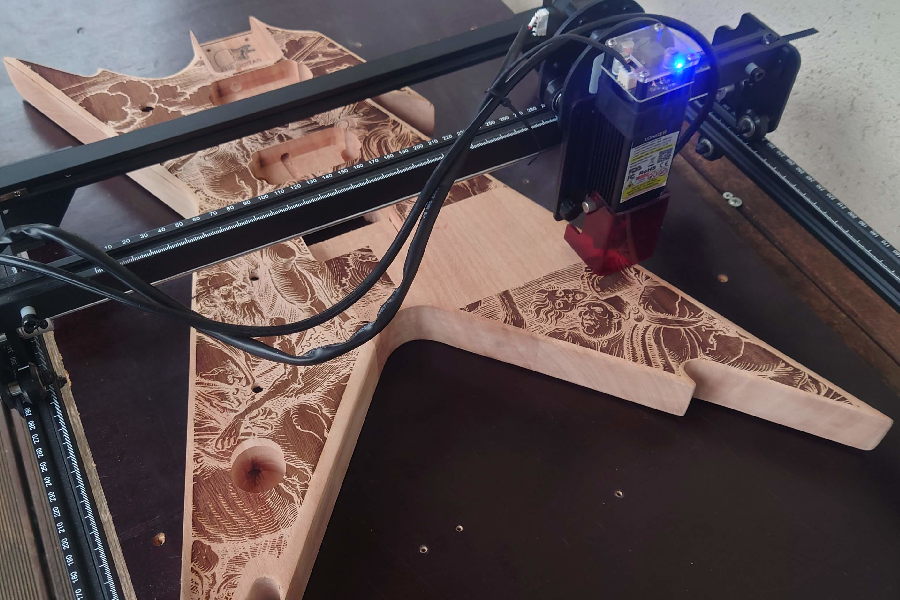

B.C. RICH CUSTOM GUITAR SHOWCASE

- The Guitar Fabrik

- 1 may 2025

- 175views

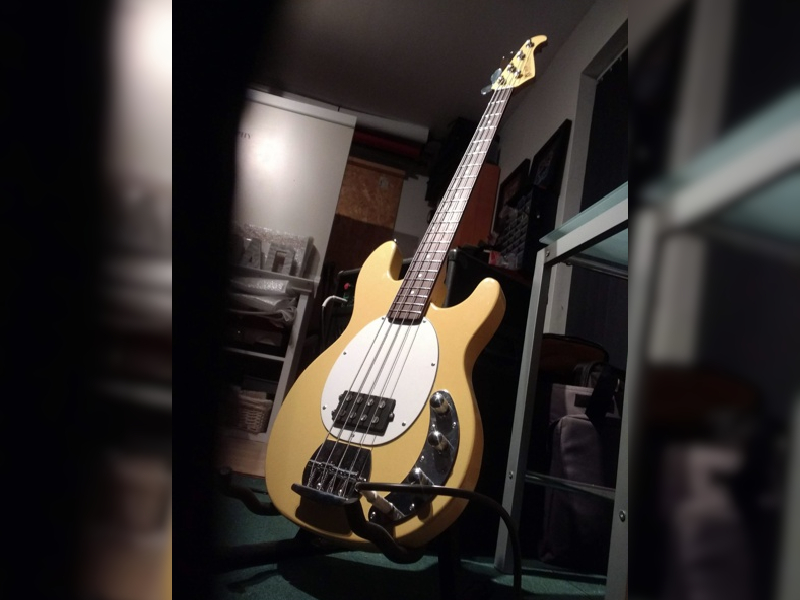

MUSIC MAN CUSTOM BASS SHOWCASE

- The Guitar Fabrik

- 28 abr 2025

- 724views

UK

UK US

US FR

FR DE

DE IT

IT